T

he Trump administration is pushing economic measures—tariffs, regulatory changes, and easier credit—to make U.S. manufacturing more competitive than overseas production. In earlier posts I examined how Texas could capture a larger share of new U.S. manufacturing. The state must meet several key prerequisites for a thriving industrial base. The previous installment focused on electric power; this one turns to water.

Water is a critical, yet variable, cost for manufacturers. There is no single price that fits all uses. Building a new supply—whether by drilling, damming, or recycling—requires capital. After covering basic drinking, sanitation, and cooking needs, water prices are driven by market forces. The economics of additional supply must be weighed against the benefits of that extra water. A gallon can serve many manufacturing processes, each yielding different returns. Factories use more water per employee than office or service firms, and the water intensity per dollar of output varies by product.

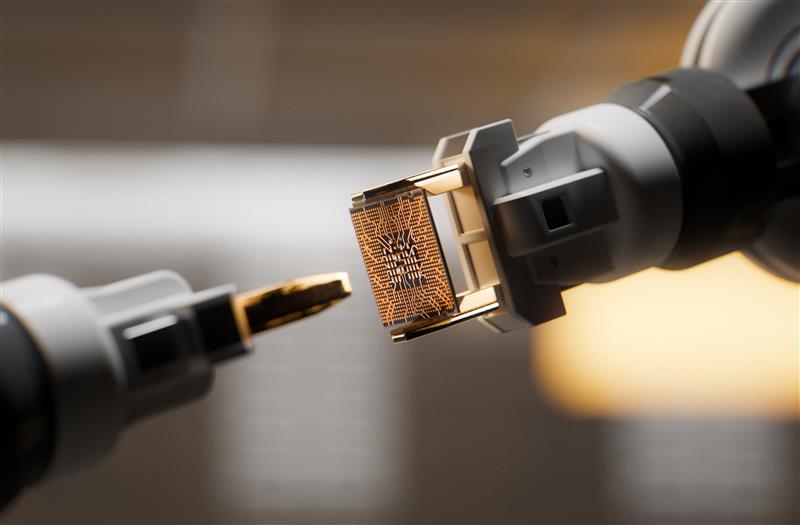

Consider paper and semiconductors, both water‑intensive sectors. Roughly 150 notebook sheets (about a dollar of paper) consume two gallons of water. The same two gallons can produce $5–$10 of high‑quality CPU chips, a fraction of a chip. Thus, a chip plant generates far more economic value per gallon than a paper plant. Both industries thrive in Texas, but their water cost sensitivities differ. Paper manufacturers prefer locations with cheap water, such as East Texas, where rainfall and pulp resources are abundant. Semiconductor firms can tolerate higher water costs because their products command high prices and can incorporate on‑site purification and recycling.

New semiconductor plants are emerging across the U.S., from wet New York to arid Phoenix. Texas‑based expansions by Texas Instruments and Samsung fall between these extremes, benefiting from moderate water availability. Texas’s diverse industrial mix—chemicals, petroleum, metals, paper, food—includes many high‑water‑use sectors. This foundation positions the state to attract further investment, especially in high‑value fields like electronics, machinery, and transportation equipment. Many regions already have, or can develop, cost‑effective water supplies to support these industries.

Continued investment in water infrastructure will enable Texas manufacturers to use water efficiently. The next series will examine transportation needs for manufacturing. Views expressed on The 338 belong to the authors and do not reflect endorsement by the Texas Real Estate Research Center, Division of Research, or Texas A&M University.